Summit Pump

Since 1982, Summit Pump has manufactured quality pumps and pump parts for industry worldwide. The company mission statement is more than just a plaque on the wall; it is how they strategically go to market. They will "provide quality pumping products in a timely manner, at a fair market price". Located in Green Bay, Wisconsin we are a privately held and financially strong company. They sell their products worldwide via a dedicated and exclusive distribution network. They pride ourselves in being the Best Value in the market.

Pump Trac Ltd. is in no way indicating we are supplying OEM parts or an authorized distributor.

We carry the following:

2175 Stock/Process Pump Model

Features

- Rear pull-out

- Efficient parts interchangeability

- Sacrificial wear items

- Double wall volute on larger sizes

Applications

Pulp & Paper:

Cleaners, filtrate, liquor, screen rejects

Steel:

Cooling water, descaling, slurries, tailings

Food:

Beet and cane sugar, cane juices, fruit pulp, wet corn milling

General:

Manure transfer, mine water, waste treatment

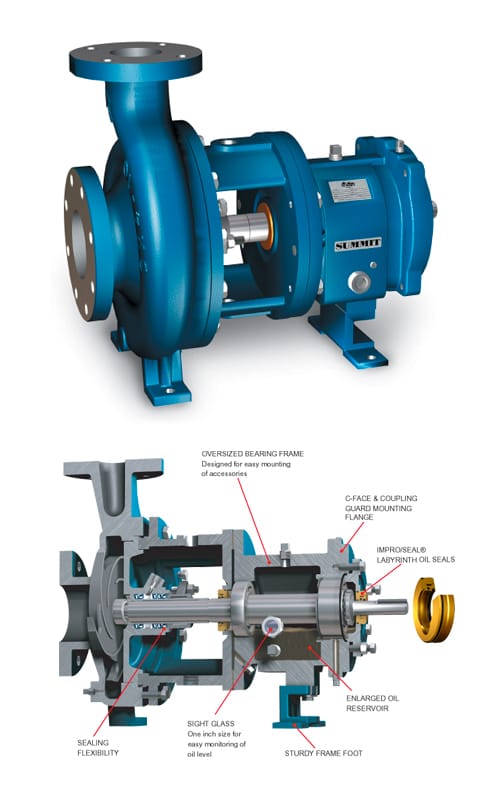

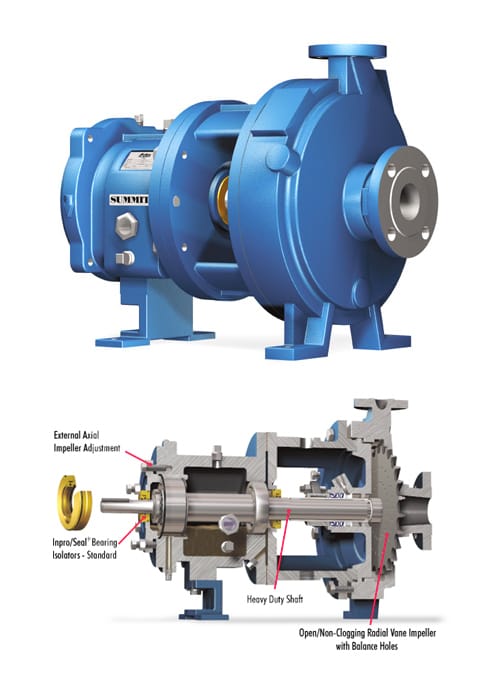

2196 ANSI Dimensional Model

Features

- Capacities to 6000 gpm

- Heads to 730 feet

- Pressures to 375 psi

- Temperatures to 700 degrees F

- Back pull out design

- External impeller adjustment

- Maximum interchangeability

- Standard bronze Inpro® labyrinth seals

- Heavy duty shaft & bearings

- Rigid frame foot

- Fully open impeller

- Extra large oil sump

- Optional Features

- Finned-tube Oil Cooler: Can be installed in field

- Multiple stuffing box cover options available

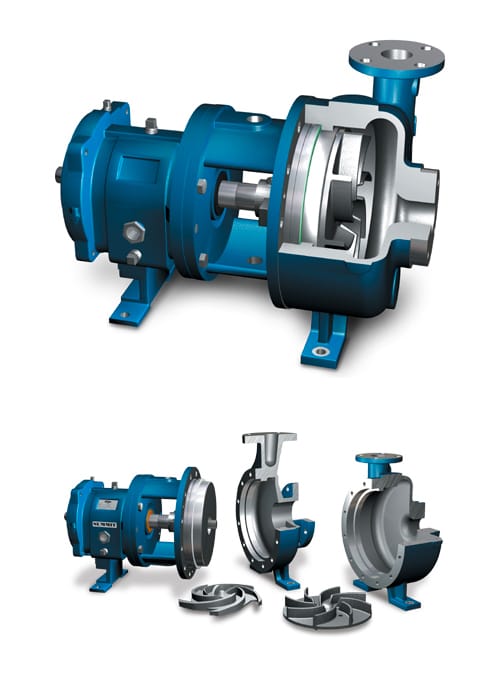

2196 R

Features

- Utilizes your existing 2196 power end and ANSI bolt pattern.

- Handles fibrous and shear sensitive materials

- Minimizes degradation of solids

- Available in 5 different sizes and a variety of materials

2196 Low Flow High Head Pump

Features

- Radial vane impeller with balance holes

- Interchangeability with existing ANSI pumps

- Circular non-expanding case

Benefits

- Reduced shaft vibration

- Lower NPSHr

- Lower seal chamber pressure

- Extended MTBF on the pump and mechanical seal

Applications

- Additive Chemicals

- Batch/Continuous Chemical Reactors

- Chemical Dryers

- Chemical Process

- Condensate Service

- Evaporators

- Petro Chemical Service

- Prototype Processes

- Shower Service

- Seal Water

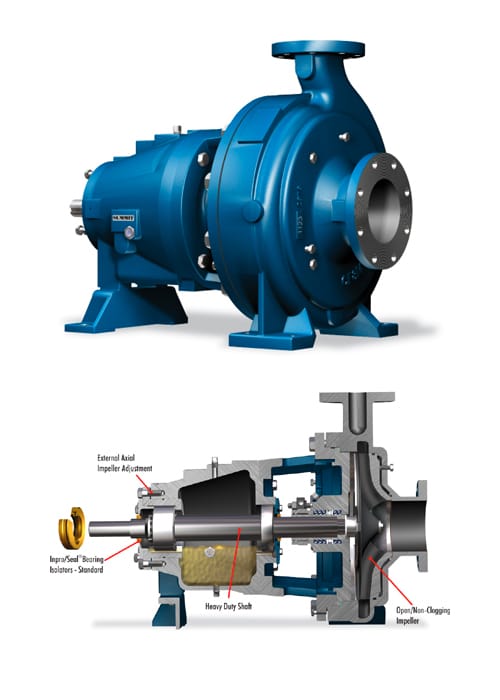

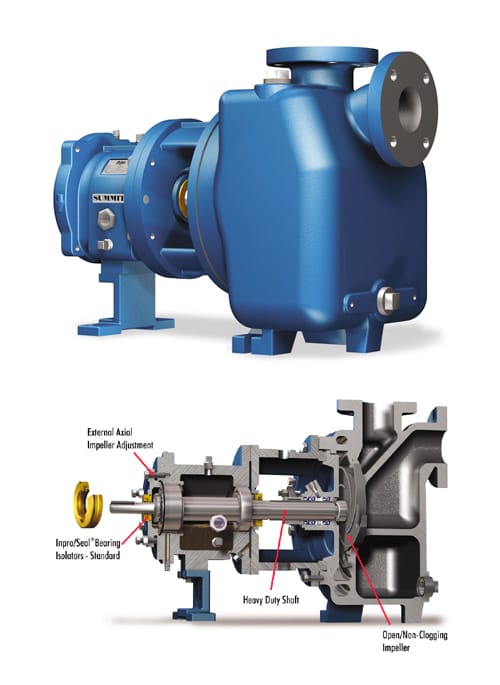

2796 Self Priming Process Pump

Features

- Rear pull-out

- External axial impeller adjustment

- Inpro/Seal bearing isolators standard

- Open non-clogging impeller

Applications

- Chemical Transfer

- Industrial Sump

- Mine Dewatering

- Bilge Water Removal

- Filter System

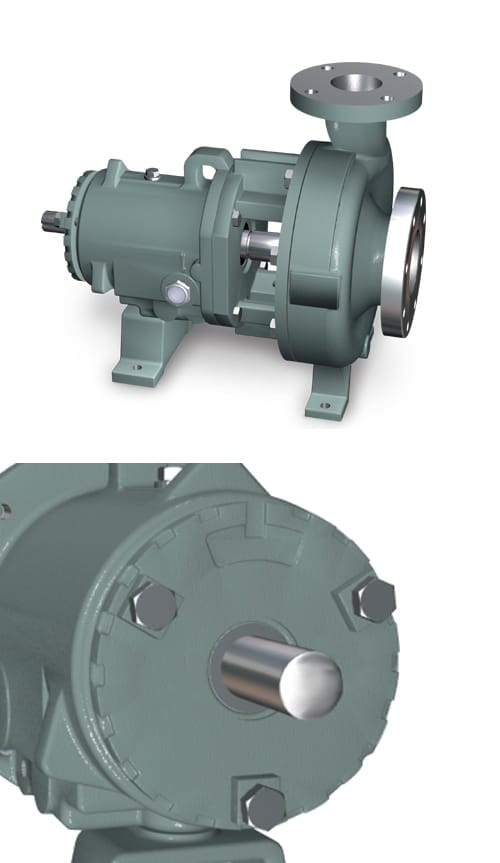

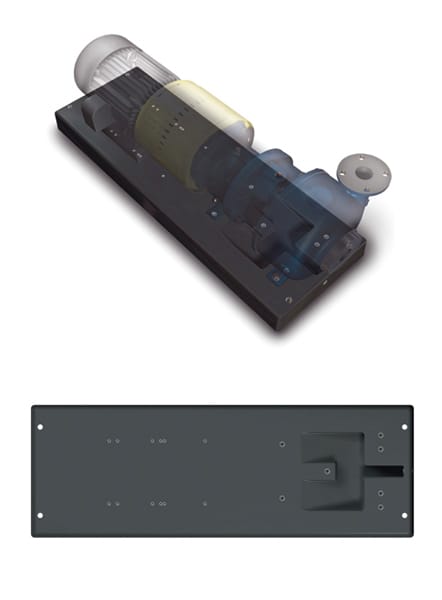

Close Coupled/framed Mounted

Features

- Summit CC & FM pumps are horizontal, end suction, centrifugal pumps designed for general service such as water, solvents, light oils, non-corrosive chemicals, coolants and brines. Available in capacities to 2300 GPM and heads to 200 feet, these pumps are an economical and dependable solution for your pumping needs. All flanges are 125lb ANSI B16.1 rating, NPT connections are standard on 6" and 8" sizes. A renewable bronze shaft sleeve is standard on cast iron pumps, and a 316SS shaft sleeve is standard on alloy pumps.

- Close Coupled Pump - Model CC

- The close coupled pump is directly mounted to a NEMA "C" face motor, and designed to use minimal space. Motors with TEFC frames use a standard mechanical seal (JM frame), or packing(JP frame). ODP motors, and stainless steel shafts are optional.

- Frame Mounted Pump - Model FM

- Frame mounted pumps are constructed with a rigid bearing frame, flexibly coupled, and mounted on a fabricated steel base with optional drip pan. Casings, adaptors, and bearing frames share mating registers for maximum interchangeability. Coupling guards meet ASME B 15.1 specifications.

- Interchangeable Parts

- Component parts, of similar sizes, are interchangeable between frame mounted and close coupled pumps. This means less spare parts inventory and fast delivery of required parts.

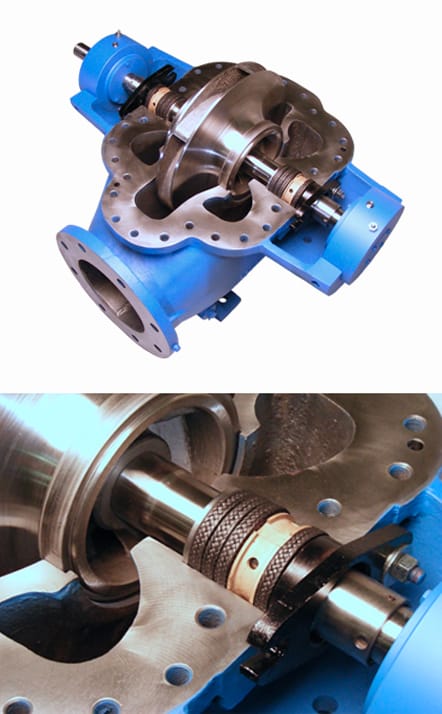

Model Clark III

Features

- Conforms to ASME B73.1M (ANSI)

- Semi-open reverse vane impeller

- Capacities to 5,000 GPM

- Head to 740 feet

- Pressures to 375 PSI

- Back pull out design

- Indexed bearing housing for ease and accurate

- mpeller adjustment

- Maximum interchangeability of parts

- Optional Features

- Multiple rear cover options

- Open impeller design available

- Finned tube oil cooler

DSR / DSN

Features

- Capacities to 6,000 GPM

- Heads to 430 feet

- Horizontal split case design

- High efficiency and low NSPHr

- Closed Impeller

- Optional Features

- Replaceable wear rings in a variety of materials

- Packing or Mechanical Seals

SL

Features

- heavy duty slurry pumps

- high chrome or rubber removable wear parts

- corrosion and abrasion resistant design

- packed box standard

SN self priming, non-clogging pumps

Features

- Self Priming

- Capacities to 3,400 gpm

- Temperatures to 160 degrees F

- Back pull out design

- Direct drive or V-belt

- Non clogging

- Hard faced mechanical seals standard

- Standard spool piece flanges

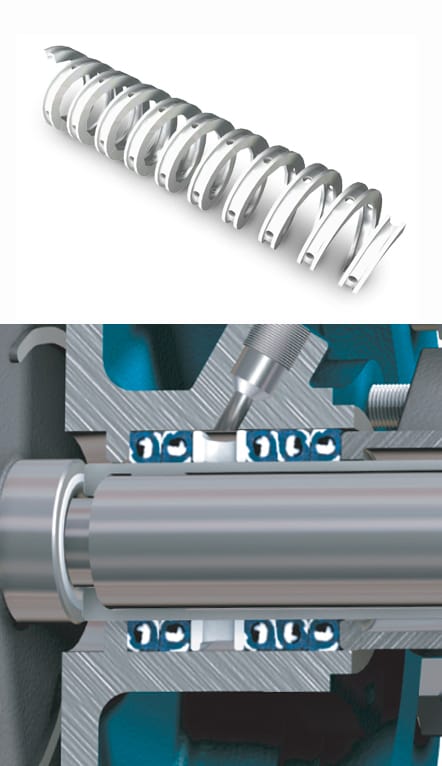

Universal Lantern Ring Material

Features

- Thermal Formed: Fits your stuffing box better, Easy to install

- One ring fits multiple stuffing boxes: Fewer orders, Lower inventory, Fewer outages

- Virgin PTFE: Temperature to 500º F, pH range from 0-14

Sizes Available

|

Cross Section |

Width |

All Sizes in 48" Lengths Custom Sizes Available upon Request

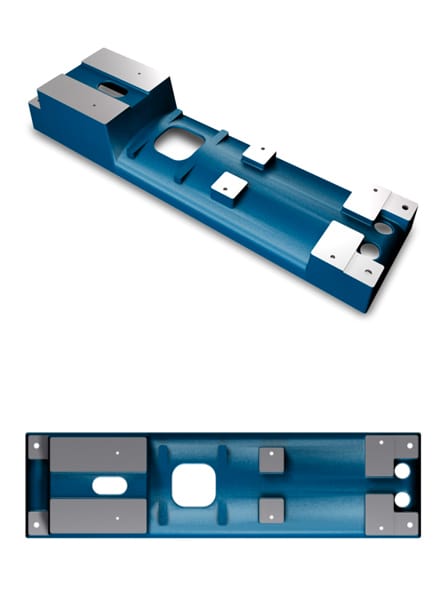

Cast Iron Base Plate

Polymer Concrete Base Plates

Features:

- ANSI B73.1 M dimensions

- Excellect corrosion resistance

- Vibration dampening superior to steel and iron

- Integrally molded catch basin

- 304 stainless steel inserts

Optional Features:

- Custom sizes

- Custom colors

- Hastelloy-C inserts

- Leveling screws

- Compatible grout

- Integrally molded grout holes

Guards

Features:

Economically priced, Safety yellow, barrel type coupling guards will bolt directly to many common models of pumps including: Goulds, Durco, Summit, Peerless and others.